MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

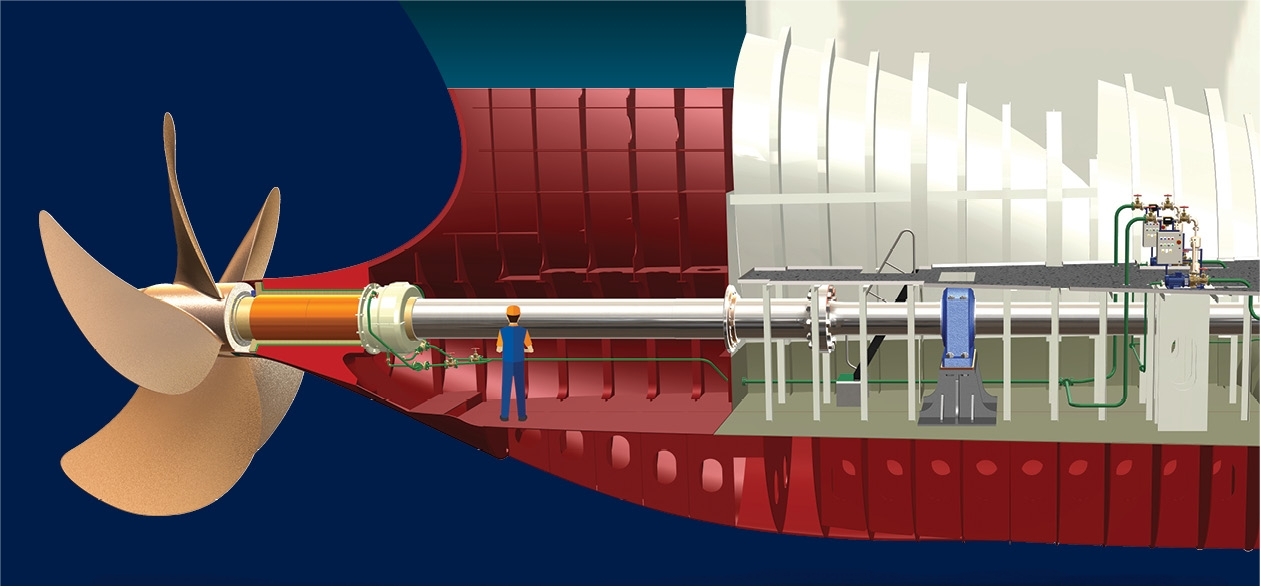

See DetailsIn the field of underwater equipment, finding a bearing material that can operate stably for long periods while possessing good lubrication performance and corrosion resistance has always been a focus for engineers and procurement specialists. The emergence of copper-based embedded self-lubricating bearings undoubtedly provides an ideal solution to this challenge. With their unique self-lubricating properties and excellent corrosion resistance, they demonstrate outstanding performance in underwater environments.

I.Underwater Machinery and Equipment

Shipbuilding and Maintenance

Application Components: Key underwater mechanical components such as rudders and propellers.

Performance: Copper-based embedded self-lubricating bearings, with their excellent corrosion and wear resistance (hardness typically reaching HB80-100 or higher), can operate stably for long periods in wet and underwater environments. For example, JDB bearings produced by Zhejiang Mingxu Machinery Manufacturing Co., Ltd. have significantly reduced maintenance costs and failure rates in ship applications thanks to their superior performance. Additionally, their low friction coefficient, typically between 0.04 and 0.15, helps reduce friction and wear, improving ship operational efficiency.

Hydraulic Radial Gates

Application Scenario: Hydraulic radial gates in hydropower stations require frequent operation in complex underwater environments.

Performance Data: Copper-based embedded self-lubricating bearings can withstand enormous water pressure while maintaining good lubrication performance, ensuring smooth opening and closing of the gates. This is attributed to their high dynamic load capacity, which meets the operational requirements of hydraulic radial gates under high water pressure, demonstrating remarkable stability and durability.

Hydraulic Cylinder Bushings

II. Hydropower Equipment

Water Turbines

Application Scenario: Bearing components such as bearing bushes and bearings in water turbines.

Performance: Through their unique self-lubricating properties, copper-based embedded self-lubricating bearings effectively reduce friction and wear, improving the operational efficiency and lifespan of water turbines. For example, JSF-5 copper-based embedded self-lubricating bearings are widely used in large and medium-sized hydropower equipment abroad. Their unique self-lubricating block design maintains stable lubrication performance under special conditions such as high temperatures, contamination resistance, and oil-free operation. In some water turbine applications, these bearings can withstand temperatures up to 350°C and sliding speeds up to 2 m/s (specific data depends on the bearing model and manufacturer), demonstrating their excellent high-temperature stability and lubrication performance.

III. Other Underwater Applications

Port Machinery

Application Scenario: Bearing components in port cranes, loading and unloading machines, and other equipment.

Performance: Copper-based embedded self-lubricating bearings can withstand heavy loads and low-speed operation in port machinery while maintaining good lubrication performance and corrosion resistance. Their base materials (such as brass and bronze) have good corrosion resistance and can operate stably for long periods in harsh environments such as humidity and salt spray.

Offshore Wind Turbines

Application Scenario: Bearing components in wind turbines.

Performance: Copper-based embedded self-lubricating bearings in offshore wind turbines can resist salt spray and seawater corrosion while maintaining good lubrication performance and stability. Their low friction coefficient and high dynamic load capacity allow the bearings to maintain good lubrication and stability while withstanding significant wind and mechanical stresses.

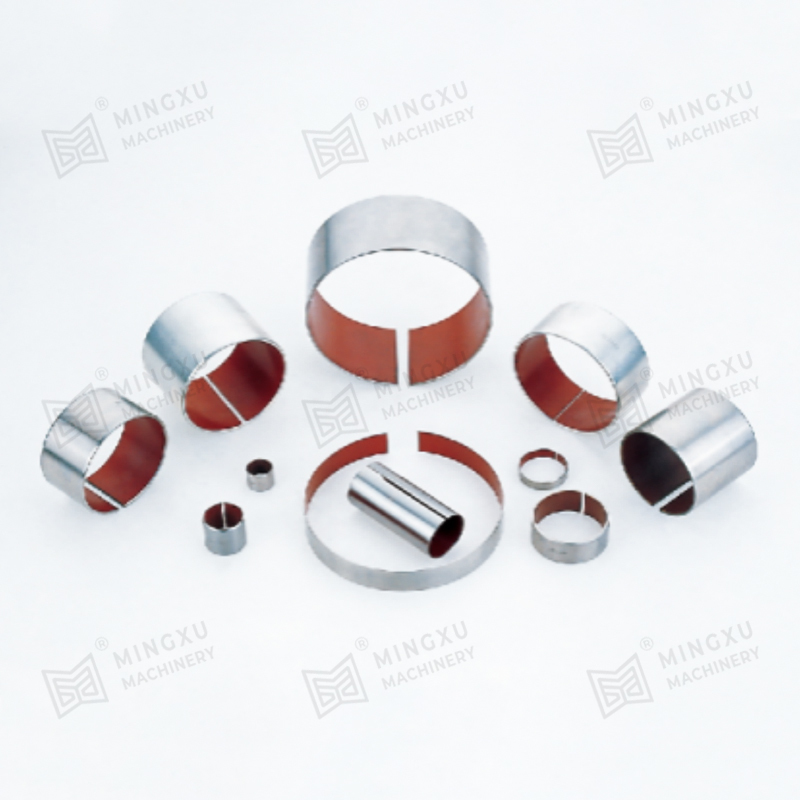

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. specializes in producing JDB copper-based embedded self-lubricating bearings (bushing, wear plate, washer, guide block, etc.), which can effectively address various underwater application scenarios, improving equipment efficiency while significantly reducing maintenance costs. If you have any product needs in this area, please feel free to contact us at: [email protected].

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

MXB-JOLP self-lubricating wear plates have good self-lubricating properties and require no external lubrication. This product has good load-bearing ca...

See Details

MXB-JGLXS guide rails are parts installed on both sides of the side core-pulling slider to ensure that the side core-pulling slider moves back and for...

See Details

MXB-JGLX self-lubricating guide rails cover multiple properties such as high wear resistance, high temperature resistance, corrosion resistance, etc.,...

See Details

MX2000-1 graphite embedded alloy bearing, MX2000-1 graphite scattered alloy bearing is an improved product of JF800 bimetallic bearing. It has the pre...

See Details

SF-1X oil-free lubricating bearing is a rolled sliding bearing with steel plate as the base, spherical bronze powder sintered in the middle, and a mix...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1S stainless steel corrosion-resistant bearing is a very effective corrosion-resistant material that is formed by rolling with stainless steel as t...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us