As a high-performance alloy material, high-strength brass has shown extraordinary application potential in many industrial fields with its unique chemical composition and mechanical properties. Its chemical formula ZCuZn25Al6Fe3Mn3 reveals its composite structure of multiple elements such as copper, zinc, aluminum, iron, and manganese. This structure gives high-strength brass high strength, high hardness, and excellent wear resistance and corrosion resistance. According to tests, the tensile strength of high-strength brass can reach more than 450MPa, and the hardness exceeds HB180, making it stand out among many alloy materials.

high-strength brass products from Mingxu Machinery

1.Composition and performance

High-strength brass:

The main components include copper, zinc, aluminum, iron, manganese, etc., with high strength and hardness, good wear resistance, and excellent corrosion resistance. Especially in seawater and other corrosive environments, the corrosion resistance of high-strength brass is particularly outstanding, which can effectively extend the service life of equipment.

H59 brass:

The copper content is about 59%, and the zinc content accounts for the balance. This alloy has the characteristics of high strength, good wear resistance, excellent electrical and thermal conductivity. At the same time, H59 brass also has good processing properties and is easy to form and process.

H59 Brass Pipe

H62 brass:

The copper content is between 60.5% and 63.5%, and the zinc content accounts for the balance. H62 brass has good plasticity, strong ductility, good corrosion resistance, and good cold and hot processing properties, suitable for a variety of processing methods.

H62 brass wire

2.Application fields

High-strength brass:

Engineering machinery: Due to its high strength and wear resistance, high-strength brass is particularly suitable for parts in engineering machinery that are subject to high loads and wear, such as gears, bearings, etc. These parts play a vital role in engineering machinery, and the excellent performance of high-strength brass ensures their reliability and durability.

Metallurgical continuous casting machines, forging presses, train brackets: In these high-temperature, high-load, and low-speed sliding parts, the corrosion resistance and fatigue resistance of high-strength brass are fully utilized, extending the service life of the equipment and reducing maintenance costs.

Ship and marine engineering: In corrosive environments such as seawater, high-strength brass has particularly outstanding corrosion resistance, so it is widely used to manufacture water pumps, valves and other components, ensuring the stable operation of ship and marine engineering.

H59 brass:

Automobile manufacturing: H59 brass is often used to manufacture key components such as engine components, transmission systems and brake systems. These components need to withstand high loads and wear, and the high strength and wear resistance of H59 brass just meet these requirements. According to incomplete statistics, the service life of automotive parts made of H59 brass can be increased by more than 30%.

Mechanical manufacturing: H59 brass is highly favored for its excellent cold and hot processing properties. In mechanical manufacturing, it is widely used to manufacture precision parts such as gears, nuts, bolts,self-lubricating bearing etc. The precision and reliability of these parts are effectively guaranteed.

Architectural decoration: H59 brass not only has a beautiful luster, but also has long-term weather resistance. Therefore, it is widely used to make architectural decorative parts such as door handles, handrails and decorative panels.

H62 brass:

Electrical field: H62 brass has excellent conductivity, making it an ideal material for manufacturing electrical components such as wires, cables and electrical connectors. Its stable and reliable conductivity ensures the normal operation of the electrical system.

Mechanical field: The plasticity and toughness of H62 brass make it suitable for manufacturing various mechanical parts and accessories. These parts play an important role in mechanical systems, and the excellent performance of H62 brass ensures their reliability and durability.

Shipbuilding: The corrosion resistance of H62 brass makes it widely used in shipbuilding. It is often used to manufacture key components such as propellers, pump shafts and piping systems, ensuring the safety and stability of ships.

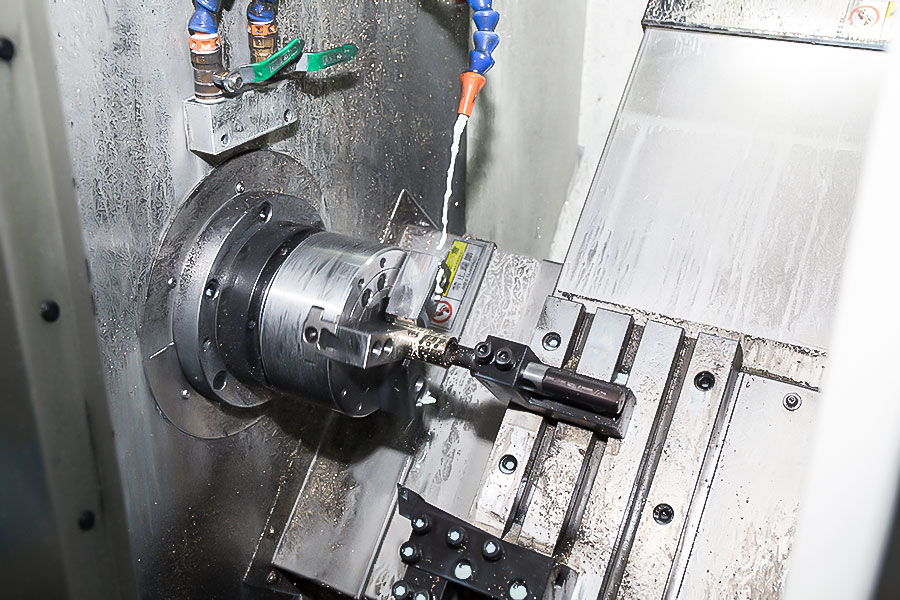

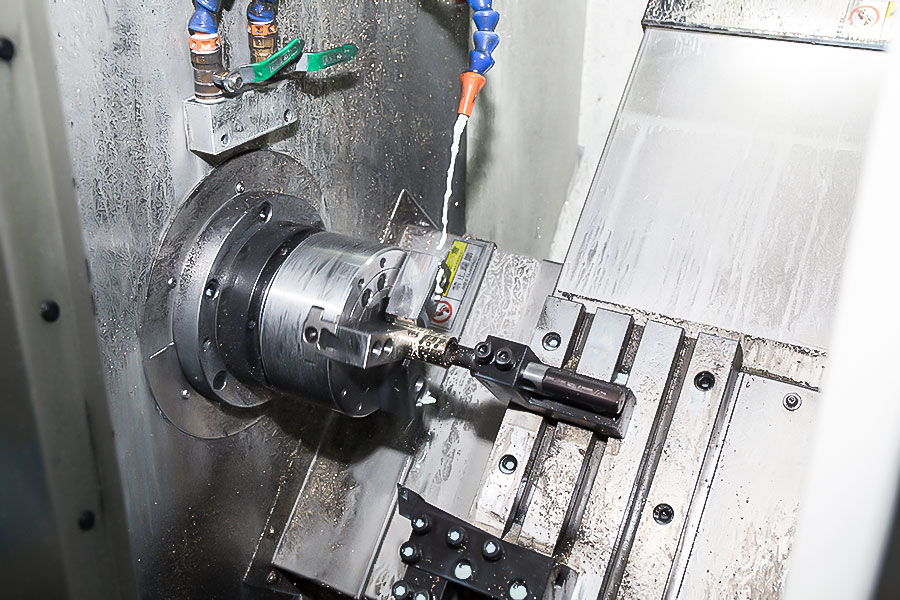

High Strength Brass Bushing Manufacturing

In summary, high-strength brass, H59 brass and H62 brass each have their own unique performance and application advantages in engineering machinery and other fields. High-strength brass plays an important role in engineering machinery and marine engineering due to its high strength, wear resistance and corrosion resistance; H59 brass is widely used in automobile manufacturing and machinery manufacturing due to its high strength, wear resistance and good processing performance; H62 brass plays an important role in the electrical field and shipbuilding due to its excellent conductivity, plasticity and corrosion resistance. In practical applications, we should choose the appropriate brass material according to specific needs and scenarios to ensure the performance, reliability and service life of the equipment.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd., as a professional copper alloy product manufacturer with more than ten years of production experience, can provide customers with customized copper alloy product solutions according to their specific needs, in order to achieve the purpose of best adapting to customer working conditions. If you have any related questions, please contact us in time: [email protected].

English

English Español

Español

Contact Us