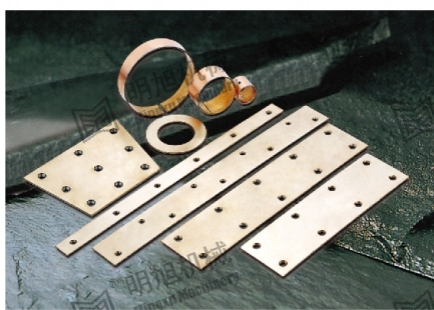

MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See DetailsWhen choosing the material for wear-resistant plate, buyers should consider where you want to use it, what performance you need, and the cost. The following are some common wear-resistant plate materials. Let's take a look at their characteristics and where they are used.

1. Carbon steel wear-resistant plate

Features: Carbon steel wear-resistant plate is very common, just like the iron pot at home, strong, and has good wear resistance.

Application: For parts such as conveyor rollers and rollers in factories that are often subject to friction and wear, carbon steel wear-resistant plate is very suitable.

2. Cast iron wear-resistant plate

Features: Cast iron wear-resistant plate is made of high-chromium cast iron, which is very hard and not afraid of being smashed. It can withstand even in high temperature and corrosive environments.

Application: In places such as steel mills, cement plants, and mines, machinery and equipment are often subject to wear and impact, such as the lining and screen plates of crushers. Cast iron wear-resistant plates are particularly durable.

3. Hard alloy wear-resistant plate

Features: Hard alloy wear-resistant plate is made of tungsten-cobalt alloy and titanium-tantalum alloy. It is as hard as stone and is particularly corrosion-resistant. It is not afraid of high temperature and high pressure.

Application: In industries such as petroleum and chemical industry, equipment parts must be able to withstand extremely high wear and corrosion, and hard alloy wear-resistant plate is their good helper.

4. Composite wear-resistant plate

Features: Composite wear-resistant plate is like a thousand-layer cake. It is made of several materials layer by layer. It is strong and wear-resistant and adaptable to various environments.

Application: In cement plants, coal mines, and metallurgical industries, machinery and equipment must be operated frequently. The bottom plate and side plate of the conveyor can greatly extend the service life by using composite wear-resistant plates.

5. Alloy wear-resistant plate

Features: Alloy wear-resistant plate is based on ordinary low-carbon steel or low-alloy steel, and a layer of alloy layer that is as hard as iron and has particularly good wear resistance is added. This layer of alloy is mainly chromium, and elements such as manganese, molybdenum, niobium, and nickel are added to make it harder and more wear-resistant.

Application: In industries such as metallurgy, coal, and electricity, equipment parts must be able to withstand great wear and impact, and alloy wear-resistant plates are their right-hand men.

6. Other wear-resistant materials

In addition to the common wear-resistant plate materials mentioned above, there are some others, such as polymer wear-resistant materials (just like plastics, but much more wear-resistant than plastics, such as ultra-high molecular weight polyethylene), and ceramic wear-resistant materials. These materials have their own characteristics and uses, and are particularly suitable for specific places.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been specializing in copper alloy products for more than ten years. The graphite self-lubricating wear-resistant plate and the steel-copper composite wear-resistant plate MX2000 series are our main products. They have extremely low friction coefficients, self-lubricating and high temperature resistance, good wear resistance and stability, and are very suitable for the needs of customers in the automotive industry and machinery manufacturing industry.

If you have any related needs, please feel free to contact us: [email protected]

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

MXB-JDBU Self-Lubricating Casting Bronze Bearing is a high-performance solid lubricating product inlaid with graphite or mos2 solid lubricant on a hig...

See Details

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See Details

MSEW JIS 20mm Standard Wear Plate is based on high-strength brass, tin bronze, steel-copper bimetal, cast iron or bearing steel. The surface is inlaid...

See Details

MX2000-2 nickel graphite dispersed alloy bearing is a new product among solid lubricating bearings. Compared with TF-1, this product has the character...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

See Details

SF-1P reciprocating bearing is a novel formula product designed based on the structure of SF-1X material and according to the special common condition...

See Details

SF-2X boundary lubricated bearing is based on steel plate, with sintered spherical bronze powder in the middle, modified polyoxymethylene (POM) rolled...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us