SF-1 oil-free bearing

SF-1 oil-free lubricated bearing is a self-lubricating sliding bearing produced by Mingxu Machinery. Its design uses steel plate as the base, the middle part uses sintered spherical bronze powder, and the surface is rolled with a mixture of polytetrafluoroethylene (PTFE) and lead. This design makes the SF-1 oil-free lubricated bearing have the characteristics of low friction coefficient, wear resistance, good corrosion resistance and oil-free lubrication. The use of this bearing can reduce costs, reduce mechanical volume, avoid shaft biting and reduce mechanical noise.

The three-layer composite structure of SF-1 oil-free bearing is mainly composed of the following three parts, each of which has a specific role:

1. Steel plate layer (base layer)

Composition: The steel plate layer is usually made of low-carbon cold-rolled steel plate, and some products use copper alloy plate as the base (called copper back type).

Function: Provide sufficient mechanical strength and dimensional stability to ensure that the bearing is not easily deformed when under pressure.

As the assembly and positioning basis of the entire bearing, ensure the accuracy and stability of the bearing during installation.

2. Copper powder layer (middle layer)

Composition: The copper powder layer is composed of sintered spherical bronze powder.

Function: Connect the steel plate layer and the plastic layer to enhance the bonding strength between the two layers.

During the operation of the bearing, it can transfer heat in time to prevent performance degradation or damage caused by overheating.

Auxiliary friction reduction, although not directly involved in lubrication, but through the synergy with the steel plate layer and the plastic layer, it improves the overall friction and wear performance of the bearing.

3. Plastic layer (friction surface layer)

Composition: The plastic layer is mainly made of polytetrafluoroethylene (PTFE) and other wear-resistant lubricating materials (such as a mixture of lead).

Function:

Provides wear resistance and self-lubricating functions. Polytetrafluoroethylene is a material with the smallest friction coefficient among plastics to date, which can significantly reduce the friction and wear of the bearing during operation.

Under oil-free lubrication conditions, it can maintain long-term good operating performance and extend the service life of the bearing.

It has good chemical stability and can maintain stable performance in various corrosive media.

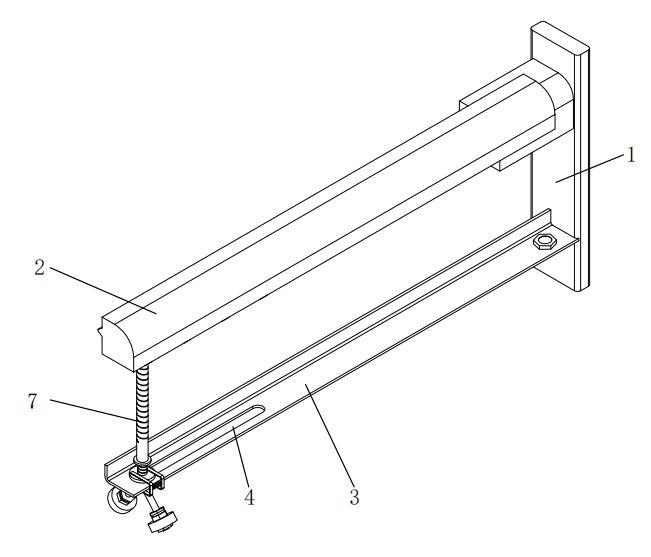

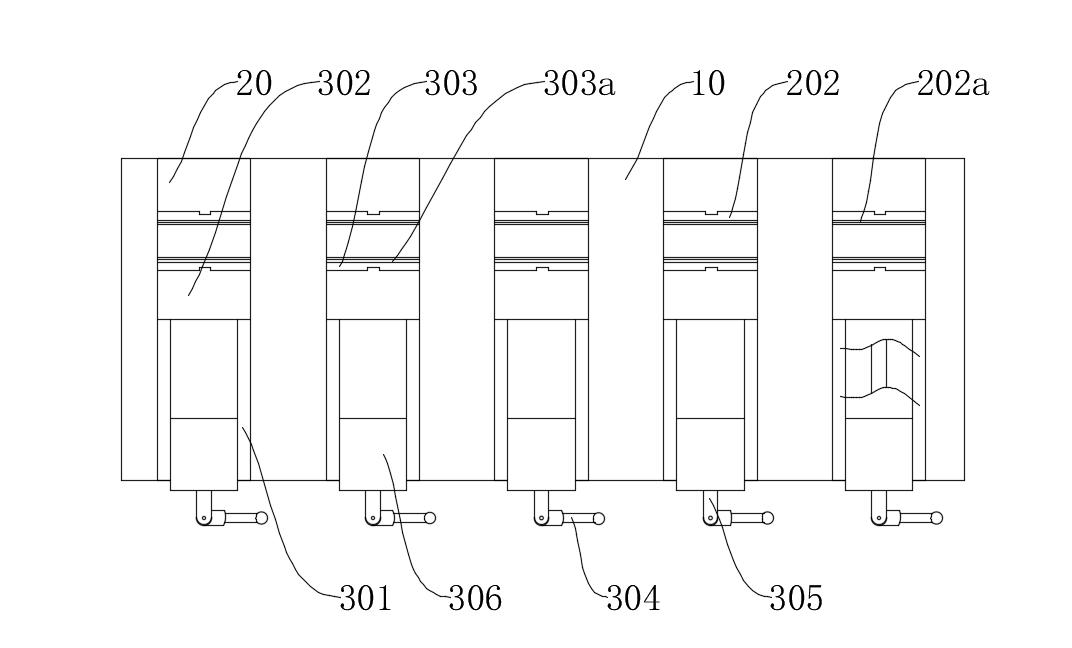

Plastic layer; 2. Copper powder layer; 3. Matrix layer

Comprehensive effect

The three-layer composite structure of the SF-1 oil-free bearing provides mechanical strength and dimensional stability through the steel layer, the copper powder layer transfers heat and assists in friction reduction, and the plastic layer provides wear resistance and self-lubrication, which together realize the efficient and stable operation of the bearing under oil-free lubrication conditions. This structure makes the SF-1 oil-free bearing perform well in high-speed and low-load application scenarios such as motors, office machinery, and shock absorbers. It is also suitable for oil-free lubrication occasions such as high temperature, low temperature, vacuum, water and other corrosive media.

English

English Español

Español

Contact Us