MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

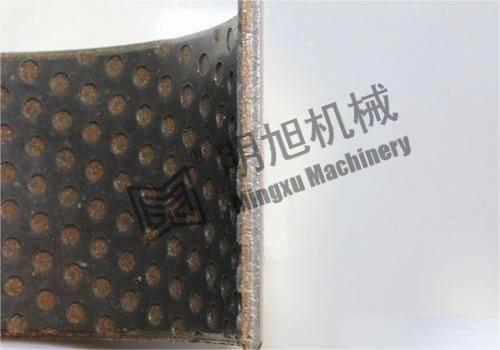

Three-layer structure of SF-2 boundary lubrication bearing

SF-2 boundary lubrication bearing uses steel plate as the matrix, sintered spherical bronze powder in the middle, rolled modified polyoxymethylene (POM) on the surface, and contains oil storage pits. This structural design makes it suitable for specific working conditions.

The three-layer composite structure of SF-2 boundary lubrication bearing has a unique composition and respective functions. The following is a detailed analysis:

1. Composition of the three-layer composite structure

Steel back layer (matrix layer)

Material: Generally high-quality carbon structural steel cold-rolled thin steel plate or steel strip with a carbon content of less than 0.25%. If necessary, surface electroplating copper or other treatments can be performed.

Function: Provide the mechanical strength of the bearing and the basis for assembly positioning, ensure that the bearing is not easily deformed when under pressure, and ensure the stable installation of the bearing in the equipment.

Porous sintered bronze layer (middle layer)

Material: bronze powder, grade CuSn10 or QFQSn8-3, thickness is about 0.3mm. The selection of these materials ensures that they comply with the corresponding industry standards, such as JB/T7380 or JB/T6649. The copper alloy layer can also be made of other materials after negotiation between the supply and demand parties.

Function: As a bridge connecting the steel backing layer and the plastic layer, it enhances the bonding strength between the two layers. At the same time, the porous structure of the bronze layer helps to transfer and disperse heat, preventing performance degradation due to overheating. In addition, it also plays a certain clamping role on the plastic layer, ensuring the overall stability and dimensional accuracy of the bearing.

Modified polyoxymethylene friction layer (surface layer)

Material: A modified mixture of polyoxymethylene (POM) and special additives. This material has excellent wear resistance, self-lubrication and dimensional stability.

Function: As the working surface of the bearing, it directly bears friction and wear. The modified polyoxymethylene friction layer can provide long-term good operating performance under oil-free lubrication conditions, reduce friction coefficient and wear rate. At the same time, the layer is also designed with an oil storage hole system, which can act as a lubricating oil reservoir and release lubricating oil when needed to further improve the lubrication effect.

2. The role of the three-layer composite structure

Self-lubricating performance: Through the self-lubricating properties of the modified polyoxymethylene friction layer, the SF-2 oil-free bearing can operate without oil or with a small amount of lubrication, reducing maintenance costs and downtime.

Carrying capacity: The combination of the steel backing layer and the bronze layer provides sufficient mechanical strength, allowing the SF-2 oil-free bearing to withstand high loads without deformation or damage.

Heat dissipation performance: The porous structure and good thermal conductivity of the bronze layer help to transfer the heat generated by the bearing during operation in a timely manner to prevent performance degradation or damage caused by overheating.

Wear resistance: The modified polyoxymethylene friction layer has excellent wear resistance and can maintain a low wear rate during long-term operation, extending the service life of the bearing.

Dimensional stability: The design of the three-layer composite structure enables the SF-2 oil-free bearing to maintain good dimensional stability under various working conditions, ensuring the accuracy and performance of the bearing.

In summary, the three-layer composite structure of the SF-2 oil-free bearing produced by Mingxu Machinery provides mechanical strength and assembly positioning through the steel back layer, the bronze layer transfers heat and enhances the bonding strength, and the modified polyoxymethylene friction layer provides self-lubrication and wear resistance, which together realize the efficient and stable operation of the bearing under oil-free or small amount of lubrication conditions.

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

MXB-JDBUF self-lubricating casting bronze bearings combine the advantages of self-lubricating and flange design. The raw materials are made of high-qu...

See Details

MXB-DX boundary oil-free bearings, equivalent to SF-2 self-lubricating or dry plain bearings, which is based on steel plate, sintered spherical bronze...

See Details

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends tha...

See Details

MXB-JSP self-lubricating wear-resistant plate is suitable for injection molding machines, automotive stamping molds, tire molds, factory machinery (ex...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MJGB oil-free injection guide bushings are standard components used in the plastic injection molding process, providing lubrication-free guidance and ...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

SF-2X boundary lubricated bearing is based on steel plate, with sintered spherical bronze powder in the middle, modified polyoxymethylene (POM) rolled...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us