1)No oil lubrication or little oil lubrication, suitable for places where refueling is impossible or difficult to refuel, and can be used with little or no maintenance;

2)Good wear resistance, small friction coefficient and long service life;

3)It has an appropriate amount of elastic-plasticity, which can distribute stress over a wider contact surface ratio and improve the bearing capacity of the bearing;

4)The static and dynamic friction coefficients are similar, which can eliminate crawling at low speeds, thereby ensuring the working accuracy of the machinery;

5)It can reduce vibration and noise of machinery, prevent pollution and improve working conditions;

6)A transfer film can be formed during operation to protect the grinding shaft, and there is no shaft bite phenomenon;

7)It has low hardness requirements for grinding shafts, and unconditioned shafts can be used, thus reducing the processing difficulty of related parts;

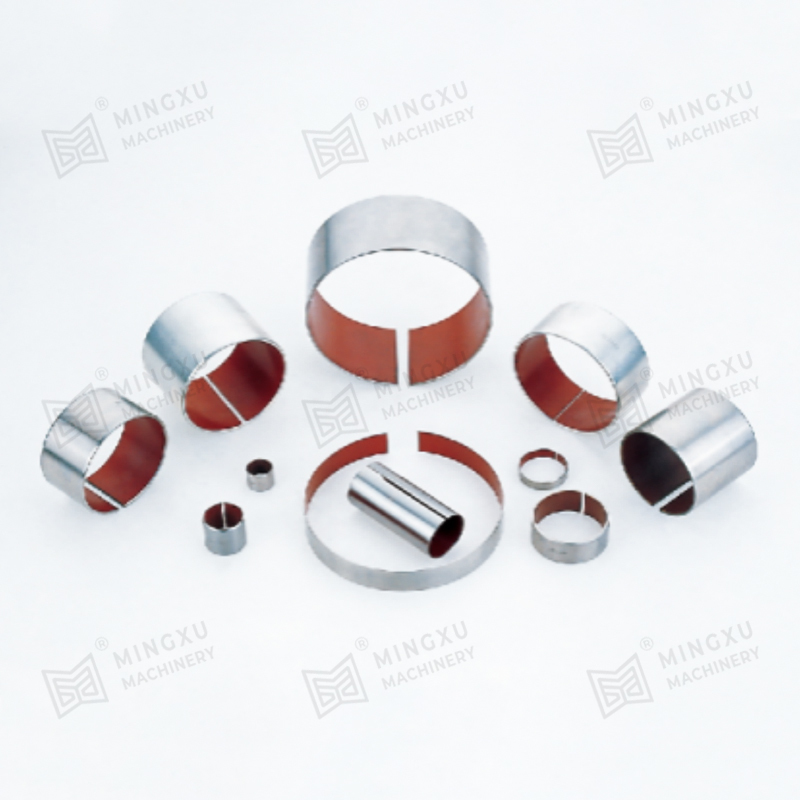

8)Thin-walled structure, light weight, can reduce the mechanical volume;

9)The bushing material is brass and can be used in corrosive media.

Through the practice of an aluminum company, the casting machine bearings were changed to oil-free

self-lubricating bearings provided by Mingxu Bearing. They have been used continuously for 15 months and are still running. The clearance between the shaft and bushings generally does not exceed 1MM and is expected to be used again. 12 months, significantly longer than the original service life (2 months).

Oil-free self-lubricating bearings can not only be well used in aluminum ingot manufacturing machines, but can also be adapted to the range of motion in oil-free, high temperature, high load, low speed, anti-fouling, anti-corrosion, and strong radiation environments, as well as in This type of bearing has wide promotion value for equipment under special working conditions where it is infiltrated in water or other solutions and cannot be lubricated at all. At present, most of the bearings used in various machinery industries are balls, needle rollers, etc., but a small number of bearings use self-lubricating bearings. It is believed that self-lubricating bearings will become the dominant bearing in the near future.

The following are some application features and advantages of self-lubricating bearings:

1. Oil-free lubrication or low-oil lubrication, suitable for places where refueling is impossible or difficult to refuel, and can be used with little or no maintenance;

2. Good wear resistance. Small friction coefficient and long service life;

3. It has an appropriate amount of elasticity and plasticity. It can distribute stress over a wider contact surface and improve the bearing's bearing capacity;

4. The static and dynamic friction coefficients are similar, which can eliminate crawling at low speeds, thus ensuring the working accuracy of the machinery;

5. It can reduce vibration, reduce noise, prevent pollution and improve working conditions of machinery;

6. A transfer film can be formed during operation. It protects the grinding shaft and prevents shaft biting;

7. The hardness requirements for the grinding shaft are low. Shafts without quenching and tempering treatment can be used, thus reducing the processing difficulty of related parts;

8. Thin-walled structure, light weight, can reduce the mechanical volume

9. The back of the steel can be electroplated with a variety of metals and can be used in corrosive media; it has been widely used in the sliding parts of various machinery, such as: printing machines, textile machines, tobacco machinery, micromotors, automobiles, motorcycles and agricultural and forestry machinery etc.

English

English Español

Español

Contact Us