1. Working principle of self-lubricating slider

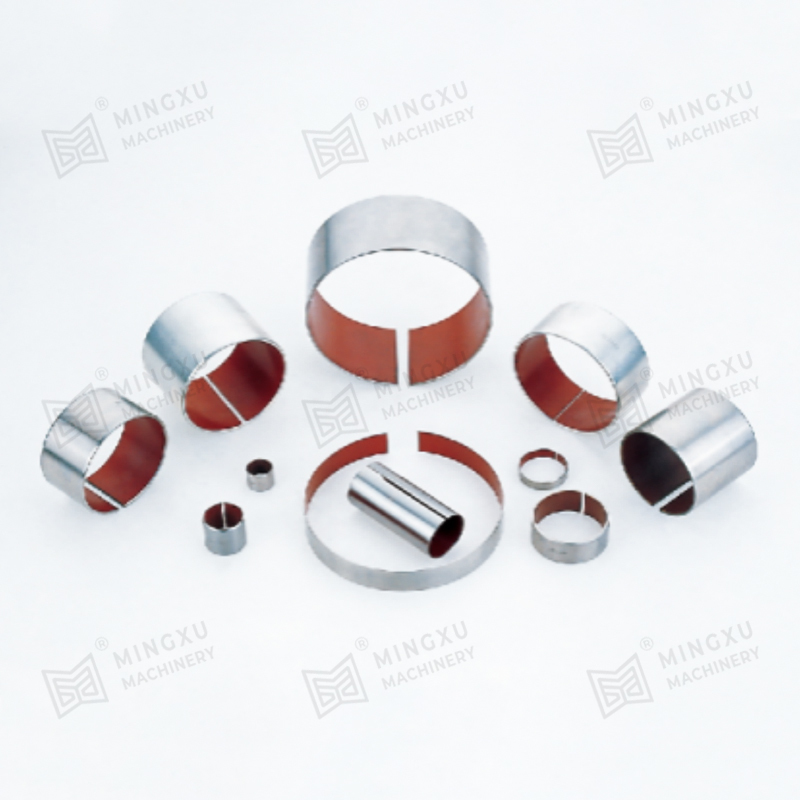

The self-lubricating slider is a special machine part that contains a certain amount of solid lubricant inside, which can reduce the friction between metal surfaces. During use, the solid lubricant will automatically release as needed and form a lubricating film plays a lubricating role.

2. Advantages of self-lubricating slider

(1) No refueling and maintenance required, low maintenance cost;

(2) Good wear resistance and long life;

(3) It has a wide operating temperature range and can work normally at higher or lower temperatures;

(4) Environmentally friendly and non-toxic.

Self-lubricating sliders have a wide range of applications and are especially suitable for use in environments with high temperature, high pressure, high load, multiple seals or poor flow lubrication conditions, such as machine tools, heavy machinery, automobiles, rail transit, aircraft, ships, metallurgical fields, etc.

4. Frequently Asked Questions

1. How to maintain the self-lubricating slider?

Answer: The self-lubricating slider does not require special maintenance. You only need to clean the surface debris before installation.

2. In what circumstances is the self-lubricating slider not suitable?

Answer: Self-lubricating sliders are not suitable for long-term overload or ultra-high temperature environments.

3. What is the difference between self-lubricating slider and traditional slider?

Answer: The self-lubricating slider can automatically release lubricant and reduce the friction between metal surfaces; while the traditional slider requires additional oiling and maintenance to maintain the lubrication state.

5. Conclusion

The self-lubricating slider is a mechanical part that does not require additional oil. It has the advantages of low maintenance cost, long life, and has a wide range of applications. Under the right environment, the use of self-lubricating sliders can help improve the stability and life of mechanical equipment.

English

English Español

Español

Contact Us