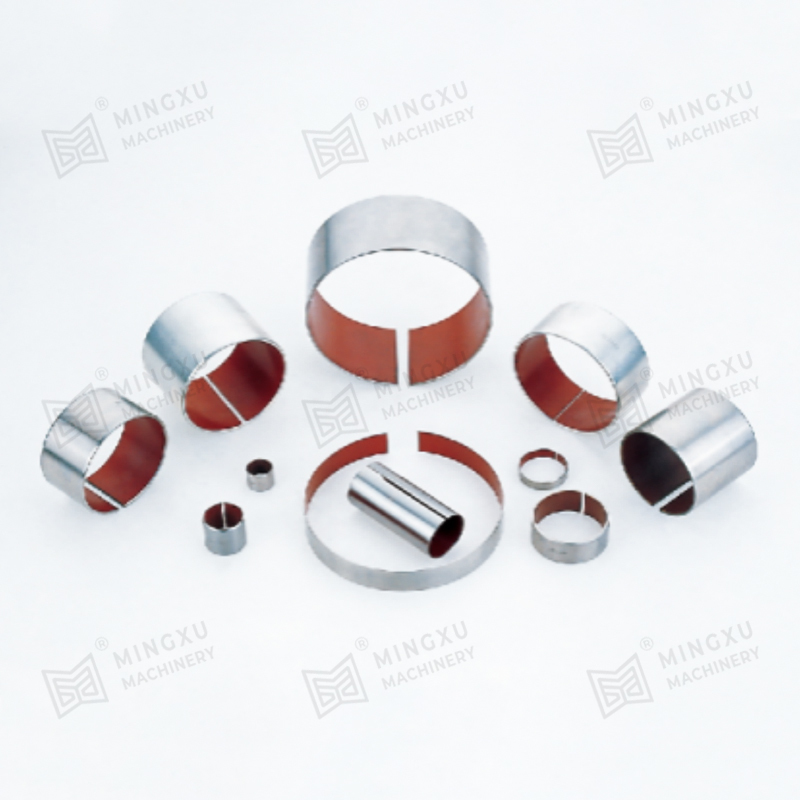

H62 brass sleeves

Main characteristics and applications of H62 brass sleeve

H62 brass sleeve is a copper alloy material widely used in the industrial field. Due to its excellent performance and high cost performance, it has become the preferred material for many mechanical parts. The copper content of H62 brass is about 62%, and the remaining components are mainly zinc, and may contain a small amount of other elements such as iron and lead. Such a composition ratio gives the material good mechanical properties, corrosion resistance and processability.

Main characteristics and advantages of H62 brass sleeve:

1. Excellent mechanical properties

H62 brass sleeve has good mechanical properties, especially its plasticity in hot and cold states. It can adapt to various complex forming processes such as deep drawing, bending and extrusion, and is suitable for making parts such as bearings, bushings and sleeves with complex structures. Its excellent plasticity enables H62 brass sleeve to maintain stability and high precision during the manufacturing process.

2. Good wear resistance and corrosion resistance

H62 brass sleeve has good wear resistance in general industrial environments, and can effectively reduce wear and extend the service life of components even during long-term friction. At the same time, its corrosion resistance is sufficient to cope with most environments, especially in environments with high humidity and heavy air pollution, and can resist mild oxidation and corrosion.

3. Easy to process and weld

H62 brass sleeve has excellent processability and is easy to process precisely to meet high-precision design requirements. This allows it to effectively control dimensions and tolerances during production to ensure the quality of parts. H62 brass sleeve also has good weldability and brazing properties, and can be easily connected to other metal materials to meet various assembly requirements.

4. High strength and high temperature resistance

H62 brass sleeve has high strength and hardness, and can still maintain stable performance under high-load working conditions. At the same time, it has good high temperature resistance and is suitable for use in high temperature environments, such as engine parts, pump bodies and valves.

5. Economical

Compared with other copper alloy materials, H62 brass has a lower raw material cost and superior processing performance, which can effectively reduce production costs and improve production efficiency. For applications that seek cost control while ensuring performance, H62 brass sleeve is an ideal choice.

6. Wide range of applications

H62 brass sleeves are widely used in many industrial fields, such as machinery manufacturing, automobiles, aerospace, chemicals, electrical equipment, instrumentation, etc. In key components such as bearings, bushings, valves, pumps, etc., H62 brass sleeves have a wide range of applicability, especially in environments that require wear resistance, corrosion resistance and oxidation resistance.

· Mechanical industry: commonly used in bearings, bushings, sleeves and other parts.

· Automobile industry: as a key material for engine parts, gearbox parts and transmission devices.

· Instruments and electrical appliances: suitable for equipment that requires high strength, good conductivity and corrosion resistance.

· Pumps and valves: used for parts such as pump bodies, valve seats and valve liners to ensure wear resistance and long-term use.

7. Strong customizability

H62 brass sleeves can be customized in different sizes, shapes and surface treatments according to customer needs. Surface treatments such as tinning, coating or special corrosion resistance treatment can further enhance its performance and meet the requirements of different applications.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the research and development and production of copper alloy parts and self-lubricating bearings for more than ten years, and has rich production experience and technical accumulation. Please feel free to contact us for any product and technical questions.

English

English Español

Español

Contact Us