In industrial production, especially under high-temperature and harsh conditions, traditional metal bearings often struggle to meet the demand for long-term stable operation. Due to friction, wear, and lubrication issues in high-temperature environments, traditional metal bearings are prone to failures, leading to equipment downtime for maintenance and even safety accidents. Therefore, finding a bearing material that can maintain excellent performance in high-temperature environments is particularly important. As a new type of high-performance bearing material, graphite self-lubricating bearings are gradually gaining attention and favor in the industrial sector due to their unique high-temperature resistance and self-lubricating properties. Compared to PEEK self-lubricating bearings, graphite bearings offer better high-temperature resistance and wear resistance, and are relatively more affordable. Although ceramic self-lubricating bearings have high hardness and good wear resistance, their high-temperature resistance is inferior to that of graphite bearings, and they are expensive.

High-Temperature Resistance

The high-temperature resistance of graphite self-lubricating bearings is primarily attributed to the high melting and boiling points of graphite material. Graphite has a melting point of 3850±50°C and a boiling point of 4250°C, allowing graphite bearings to maintain stable performance in extremely high-temperature environments. Specifically, graphite bearings can withstand temperatures above 500°C, and some special types, such as electro-graphitized bearings, can even tolerate temperatures of 450-500°C under light loads. When used in a vacuum or protective atmosphere, their temperature resistance limit can be increased to 1000°C. Therefore, graphite self-lubricating bearings can maintain stable dimensions and shapes in high-temperature environments, without softening, deformation, or failure.

Self-Lubricating Properties

Graphite self-lubricating bearings exhibit excellent self-lubricating properties, forming a layer of graphite film between the two sliding surfaces, effectively reducing friction and the coefficient of friction. This self-lubricating property allows graphite bearings to reduce friction and wear during high-speed operation, improving equipment efficiency and reliability. At the same time, the graphite film prevents direct contact between the bearing and the shaft sleeve, thereby extending the bearing's service life. In high-temperature environments, the self-lubricating properties of graphite remain stable, eliminating the need for additional lubricating oils, reducing maintenance costs, and environmental pollution.

Application Effects

The application effects of graphite self-lubricating bearings in high-temperature environments are mainly reflected in the following aspects:

Reducing friction and wear: Graphite self-lubricating bearings can significantly reduce friction and the coefficient of friction, minimizing wear between the bearing and the shaft sleeve, and extending equipment service life.

Improving operational efficiency: Due to their excellent self-lubricating properties, graphite bearings can reduce friction and resistance, thereby enhancing equipment operational efficiency.

Lowering maintenance costs: Graphite self-lubricating bearings do not require additional lubricating oils, reducing oil usage and the risk of leaks, and lowering maintenance costs and environmental pollution.

Adapting to high-temperature environments: Graphite bearings can maintain stable performance in high-temperature environments without softening, deformation, or failure, ensuring normal equipment operation.

Application Scenario Examples

Metallurgical Industry

In high-temperature equipment such as heating furnaces and blast furnaces in the metallurgical industry, graphite self-lubricating bearings are often used to support and rotate components. For example, in the transmission system of a heating furnace, graphite bearings can withstand temperatures up to several hundred degrees Celsius while maintaining stable lubrication performance, ensuring normal equipment operation.

Petroleum Industry

In petroleum extraction and processing, many devices operate in high-temperature, high-pressure, and corrosive media. Graphite self-lubricating bearings are widely used in the transmission systems of these devices, such as mud pumps and water injection pumps, due to their good high-temperature resistance, corrosion resistance, and self-lubricating properties.

Chemical Industry

In chemical industry equipment such as reactors and heat exchangers, graphite self-lubricating bearings are commonly used in agitators, shaft seals, and other components. Their high-temperature and corrosion resistance allows bearings to operate stably for long periods in high-temperature and corrosive media, reducing failures and maintenance costs due to corrosion.

Precautions

Despite the significant advantages of graphite self-lubricating bearings in high-temperature environments, the following points should be noted during use:

Select the appropriate bearing type and specification: Choose the appropriate type and specification of graphite bearing based on specific operating conditions and requirements to ensure long-term stable operation.

Pay attention to bearing cooling and lubrication: Although graphite bearings have self-lubricating properties, cooling and lubrication issues should still be considered in extremely high-temperature environments to prevent performance degradation or damage due to overheating.

Regular inspection and maintenance: Regularly inspect and maintain graphite bearings, promptly identify and address potential issues, and ensure long-term stable operation.

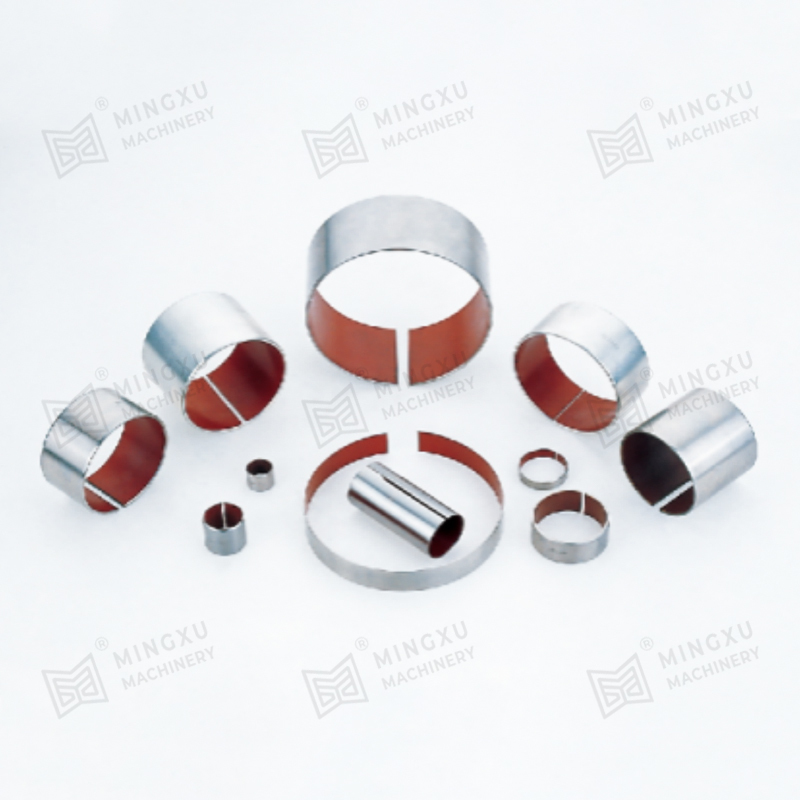

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. (oilless-bearing.com), as an industry leader, focuses on the research and production of high-temperature self-lubricating bearings, strictly controlling every aspect from material selection to testing to ensure optimal product performance. With a professional R&D team, we closely follow market trends, introduce innovative products, and establish a comprehensive quality management system to ensure product reliability and stability. We sincerely invite partners from all walks of life to explore the unlimited potential of graphite self-lubricating bearings and provide strong support for the metallurgical, petroleum, chemical, and other industries, creating a brilliant future together.

English

English Español

Español

Contact Us