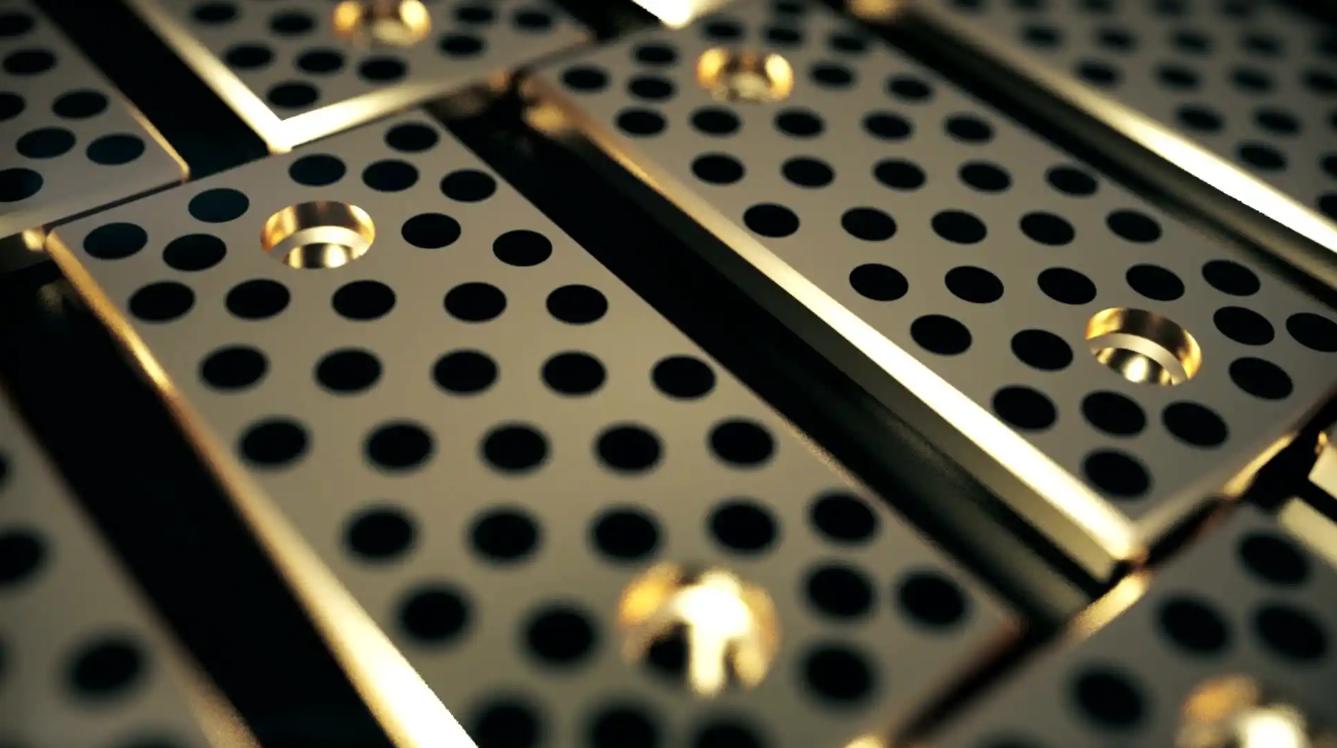

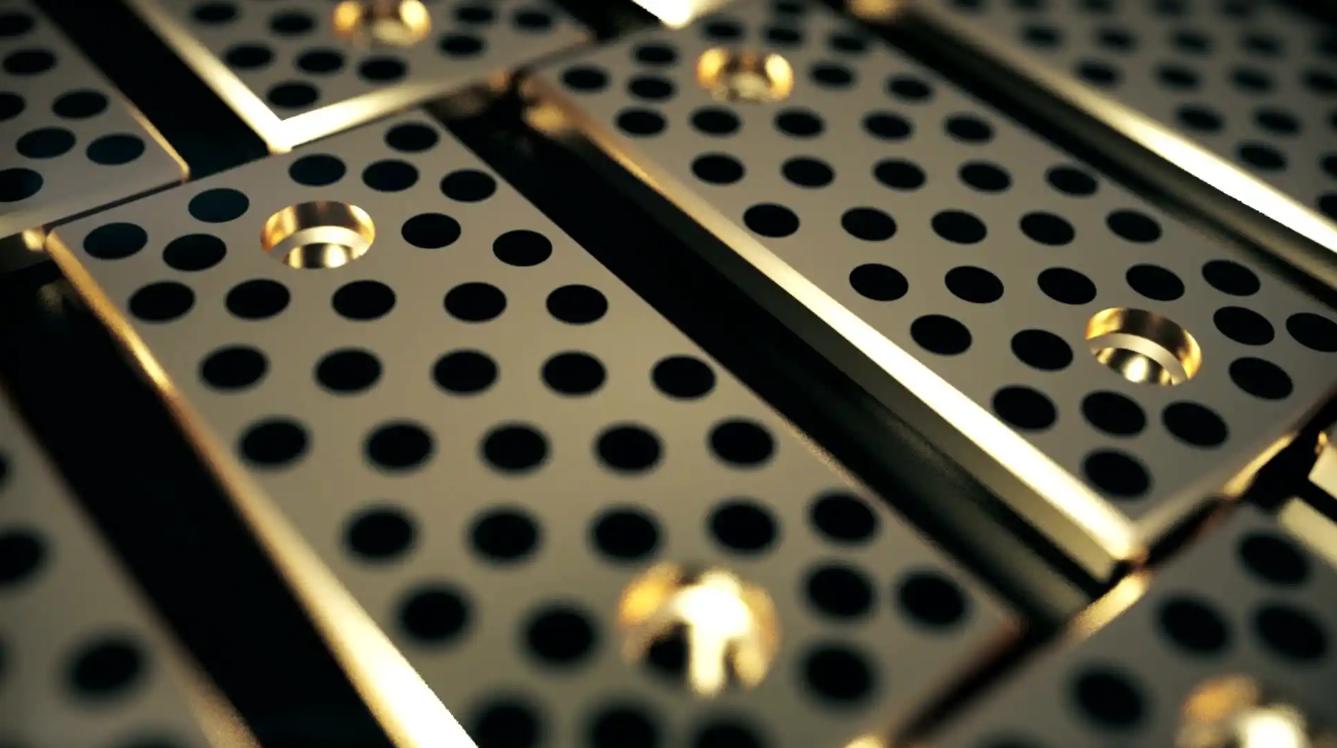

Graphite-inlaid copper alloy guide rails (such as copper-based inlaid graphite self-lubricating guide rails, high-strength brass inlaid graphite copper guide rails, etc.) are high-performance sliding guide components, usually composed of a copper alloy matrix and graphite particles uniformly inlaid therein. During operation, this guide rail releases graphite lubricant to form a solid lubricating film, effectively isolating the direct friction between the two moving surfaces, thereby reducing the friction coefficient and reducing wear. It has the characteristics of high strength, wear resistance, self-lubricating properties and high temperature resistance, and is suitable for heavy loads, high loads and occasions where conventional lubrication is not possible or maintenance is difficult. Graphite-inlaid copper alloy guide rails are widely used in many industries such as machinery, automobiles, metallurgy, and chemicals, and are an indispensable and important component in modern industry.

1. Characteristics

High strength and wear resistance:

The copper alloy matrix provides excellent strength and wear resistance, allowing the guide rail to withstand heavy and high-load applications. The application of high-quality copper alloy materials such as high-strength brass further enhances the mechanical properties and durability of the guide rail.

Self-lubricating performance: Graphite is used as a solid lubricant and is evenly embedded in specific parts of the copper alloy matrix. During the operation of the guide rail, the graphite lubricant embedded in the matrix is released to form a solid lubricating film, thereby isolating the direct friction between the two moving surfaces, reducing the friction coefficient and reducing wear.

High temperature resistance: The guide rail can remain stable at a higher operating temperature and is suitable for high temperature application environments. The maximum operating temperature of a specific model of graphite-embedded copper alloy guide rail can reach above 300°C.

Environmentally friendly: Reduced use of lubricating oil helps reduce environmental pollution. It meets the requirements of modern industry for environmental protection and sustainable development.

Good customization: The guide rail can be customized in different shapes and sizes according to different application requirements. It provides good flexibility and adaptability to meet the requirements of different equipment and systems.

Good economic efficiency: Although the initial cost may be slightly higher, it has good economic benefits in the long run due to low maintenance costs and long service life.

2.Application scenarios

Mechanical transmission system:

Such as linear slides and guide rail systems, as a component to reduce friction and improve movement stability. Applicable to the sliding guide parts of various mechanical equipment to improve the operating efficiency and precision of the equipment.

Automated production line:

Used to make sliding parts of precision equipment to ensure the stable operation and efficient production of equipment.

Play an important role in the field of intelligent manufacturing and automation.

Aerospace field:

Good adaptability to extreme temperature and pressure conditions and its excellent electrical properties enable it to be used in special environments in the aerospace field.

Playing key roles such as conductive contact points or anti-wear coatings to ensure the safety and reliability of aircraft.

Power equipment and automobile manufacturing:

In power equipment, graphite inlaid copper alloy guide rails can withstand high current and high voltage loads to ensure the stable operation of the power system.

In automobile manufacturing, it is used to make various sliding parts and guide parts to improve the durability and comfort of automobiles.

Metallurgy and chemical industry:

Excellent performance in high temperature, high pressure and corrosive environments, suitable for sliding guide parts of various metallurgical and chemical equipment.

Improved the stability and service life of the equipment.

As one of our main products, Zhejiang Mingxu Machinery Manufacturing Co., Ltd. produces self-lubricating guide rails in various models and sizes that can be customized according to customer working conditions. If you have any needs, please contact us: [email protected].

English

English Español

Español

Contact Us