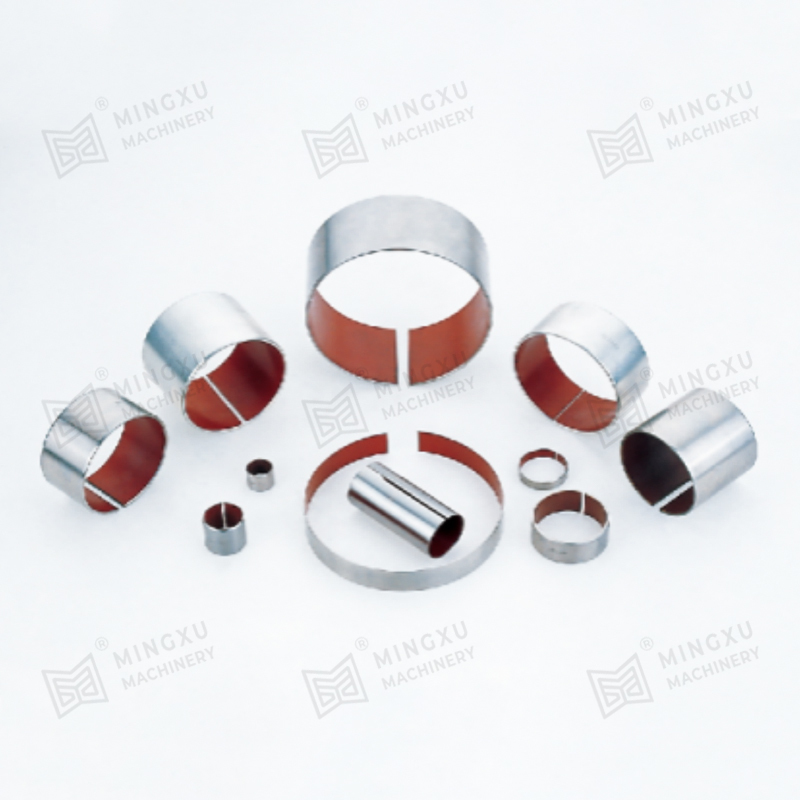

Oil-free bearings have significant advantages in load-bearing capacity compared to traditional bearings.

Its design and material selection give it excellent wear resistance and high hardness, which means oil-free bearings can withstand greater radial and axial loads. Oil-free bearings effectively reduce friction and wear through special lubrication mechanisms, such as the use of solid lubricating materials, thus improving the bearing capacity.

Oil-free bearings generally provide higher accuracy and more stable performance, which helps reduce additional loads caused by friction and vibration. The structural design of oil-free bearings also takes load distribution and balance into consideration, allowing them to better cope with complex and changing load conditions.

It can also show advantages in some special working environments. For example, in high temperature, low temperature, humid or corrosive environments, oil-free bearings can maintain a high load-bearing capacity due to their good corrosion resistance and thermal stability.

The load-carrying capacity advantage of oil-free bearings is not absolute and depends on the bearing model, specifications and application conditions. Therefore, when selecting bearings, comprehensive considerations need to be made based on actual needs and working environment.

Oil-free bearings have significant advantages in load-bearing capacity compared to traditional bearings, making them an ideal choice for heavy loads, high speeds or special working environments.

English

English Español

Español

Contact Us