The service life, wear amount, PV value, operating temperature, friction coefficient, etc. of self-lubricating bearings are all affected by conditions such as the material of the grinding shaft. The material, hardness, surface roughness and surface treatment status of the grinding shaft affect the use of self-lubricating bearings. important reason for longevity. At the same time, the above factors also affect the service life of the grinding shaft itself. Since shaft components are generally key components in mechanical equipment, the life of the shaft sleeve and counter-grinding shaft also affects the service life of the entire mechanical equipment.

Therefore, we recommend the following three points to improve the performance of shaft grinding and extend the service life of shafts and bearings.

1. Material and hardness of grinding shaft

Under normal circumstances, when using solid lubricated bearings, the material of the grinding shaft can be 35# or above high-quality carbon structural steel, Cr12 alloy steel or 95iCr alloy tool steel, etc. The above materials have been quenched, tempered, and after surface treatment, the hardness exceeds Bearing hardness can achieve ideal results. However, when hard impurities invade, shaft materials with higher hardness should be used as much as possible to achieve better results.

2. Surface roughness

When the surface roughness of the grinding shaft is too large, the convex parts of the shaft and the bearing will cut off the oil film, causing direct contact between the two. Therefore, increase the surface roughness of the grinding shaft and reduce the oil film gap as much as possible to make it close to fluid lubrication. condition, which can improve the service life of self-lubricating bearings.

3. Surface treatment

Under normal circumstances, the surface treatment of the grinding shaft can be roughly divided into the following three items: a. Improve the corrosion resistance; b. Improve the surface hardness; c. Smooth the surface and improve the lubricity.

Electroplating the grinding shaft can improve its corrosion resistance, effectively prevent rough wear, and improve lubrication performance. Similarly, when the grinding shaft rusts, the hard oxides and foreign matter entering will also cause increased wear. Therefore, it is recommended that users use beryllium hard chromium on the grinding shaft. In addition, under high load and small rocking motion, proper heat treatment of the grinding shaft will also achieve good results. Also in similar corrosive conditions such as sea water Next, it is necessary to plate the grinding shaft with two to three layers of hard chromium.

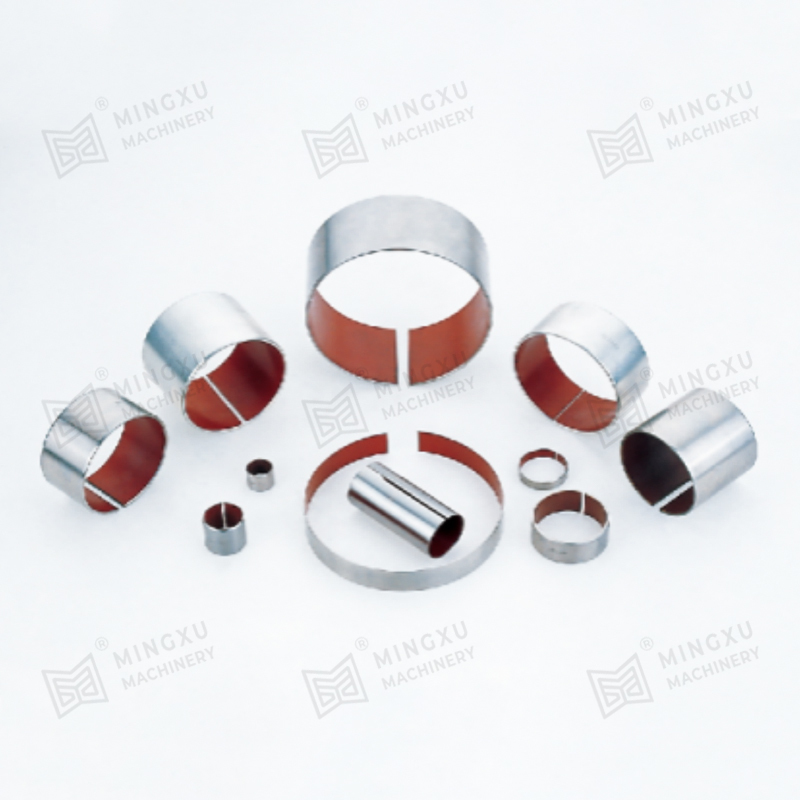

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. specializes in the R&D and production of copper alloy components and self-lubricating bearing bushings for more than ten years. It has rich production experience and technology accumulation. Please feel free to contact us at [email protected] for any product and technical questions.

English

English Español

Español

Contact Us