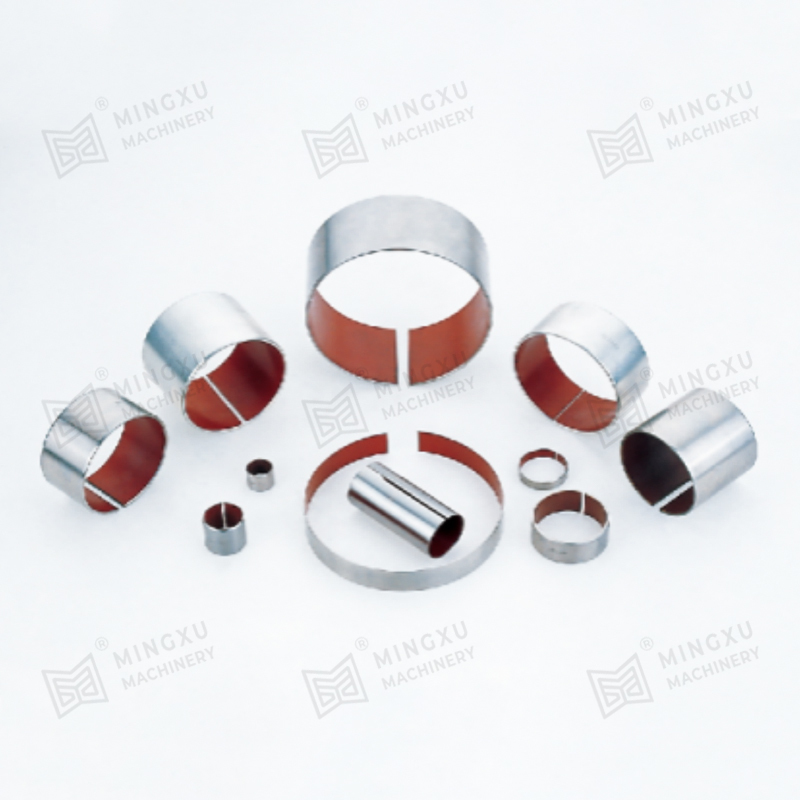

MXB-DUF Oil-Free Flange Composite Bearings

Cat:Oilless Bearing

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See DetailsSolid-lubricating bearings are uniquely suited to thrive in environments plagued by high levels of dust and contaminants, which is a common challenge in industries such as construction, mining, and agriculture. Traditional bearings often rely on liquid lubricants, which can easily become contaminated by dirt, grime, or abrasive particles. This contamination can compromise the lubricant's effectiveness, leading to increased friction, wear, and ultimately, bearing failure. In contrast, solid-lubricating bearings utilize materials like graphite, molybdenum disulfide, and PTFE (polytetrafluoroethylene), which are inherently more resistant to these harsh conditions.

One of the standout features of solid-lubricating bearings is their ability to form a protective layer between moving surfaces. This layer significantly reduces friction and wear, allowing the bearings to function smoothly even in the presence of abrasive particles. Unlike liquid lubricants, which can be washed away or degraded by contaminants, solid lubricants remain intact, ensuring consistent performance. This self-lubricating capability means that even when dust and debris infiltrate the bearing assembly, the solid lubricant continues to provide effective lubrication.

In addition to their resistance to contamination, solid-lubricating bearings are designed to operate under extreme conditions, including high temperatures and pressures. These challenging environments can exacerbate the risks associated with traditional bearings, which may rely on liquid lubricants that can evaporate or degrade. Solid lubricants, however, maintain their integrity, allowing the bearings to perform reliably without frequent maintenance or replacement.

The advantages of using solid-lubricating bearings extend beyond just operational efficiency. They can lead to significant cost savings for businesses. Reduced downtime due to bearing failure, coupled with lower maintenance needs, means that equipment can stay in service longer and operate more efficiently. This is especially crucial in industries where machinery is subject to continuous use and heavy loads.

Solid-lubricating bearings offer a robust and reliable solution for machinery operating in dusty and contaminated environments. Their ability to withstand harsh conditions without the vulnerabilities associated with liquid lubricants not only enhances their performance but also contributes to longer service life and lower operational costs. As industries continue to seek ways to improve reliability and efficiency, solid-lubricating bearings are likely to play an increasingly important role in ensuring smooth operation amid the challenges posed by dust and contaminants.

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See Details

MXB-JESW slide plates are 2-hole and 4-hole wear-resistant heavy-duty slide plates. They are standardized products and compatible with many brands, su...

See Details

MXB-JSP self-lubricating wear-resistant plate is suitable for injection molding machines, automotive stamping molds, tire molds, factory machinery (ex...

See Details

Circular guides are frequently used in automobile panel molds and large stamping molds. The mold base and unloading plate guides usually use self-lubr...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MSEW JIS 20mm Standard Wear Plate is based on high-strength brass, tin bronze, steel-copper bimetal, cast iron or bearing steel. The surface is inlaid...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

See Details

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

See Details

The SF-2S oil-free bearing, as an upgrade to the SF-2 series, stands out with its unique design concept and excellent performance. It features a solid...

See Details

Contact Us