MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

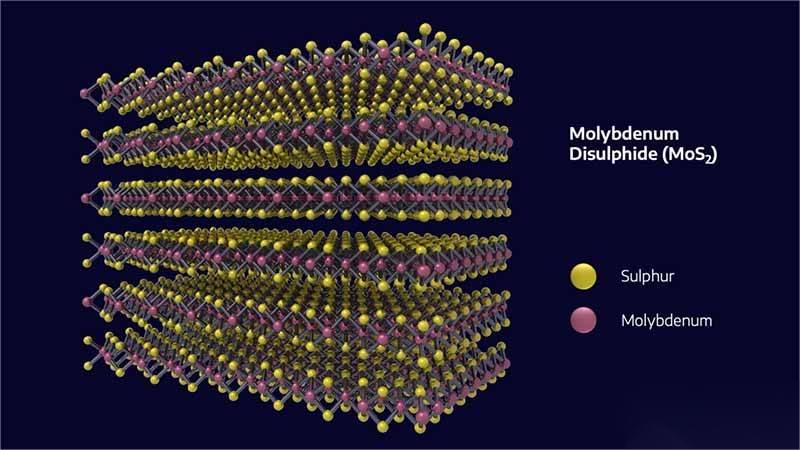

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

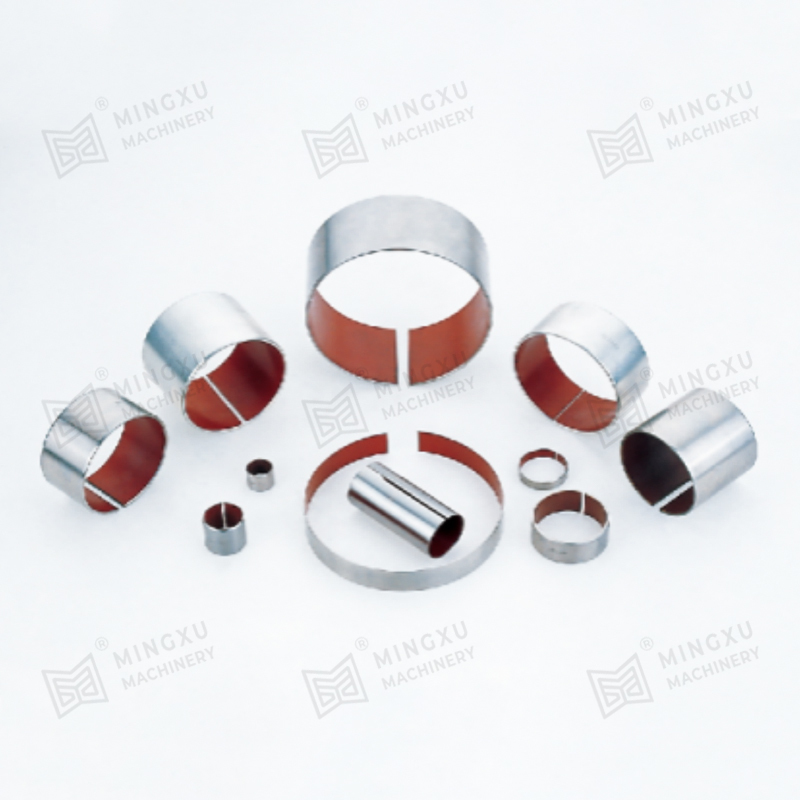

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

MXB-JDBUF self-lubricating casting bronze bearings combine the advantages of self-lubricating and flange design. The raw materials are made of high-qu...

See Details

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends tha...

See Details

MXB-JOML self-lubricating wear plates are designed to minimize friction and extend service life in industrial applications. The product is made from a...

See Details

MXB-JGLXS guide rails are parts installed on both sides of the side core-pulling slider to ensure that the side core-pulling slider moves back and for...

See Details

MGB61 NAAMS Standard Guide Bushing is a reliable solution for precise, smooth guide applications. This guide bushing is designed to meet NAAMS standar...

See Details

MJGBF oil-free injection guide bushings are components used in the plastic injection molding process to further improve manufacturing efficiency by en...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

The SF-2S oil-free bearing, as an upgrade to the SF-2 series, stands out with its unique design concept and excellent performance. It features a solid...

See Details

Contact Us